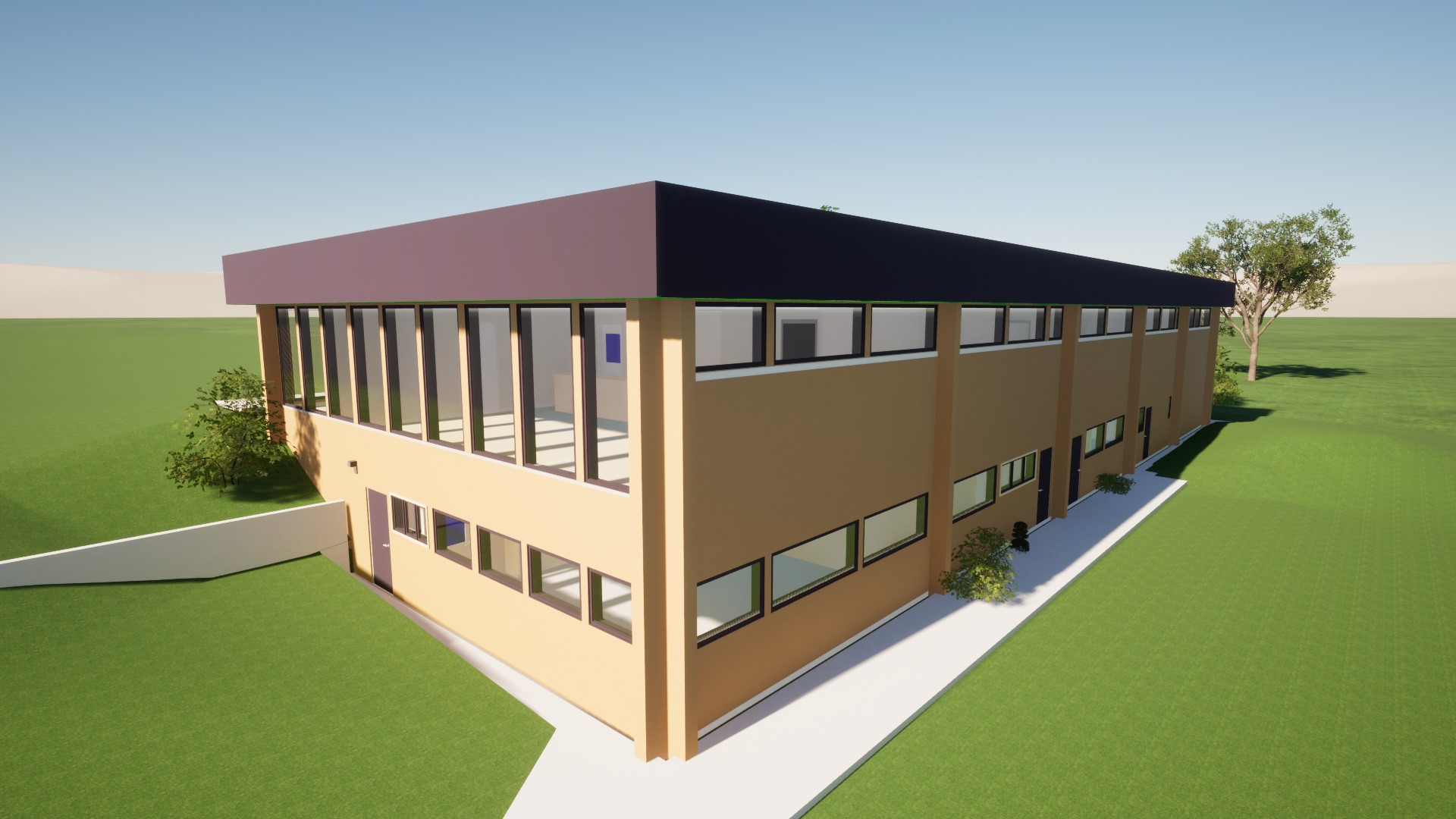

GUIDEPOST MONTESSORI, WHITE BEAR LAKE, MN

Restrictions on ceiling height take special consideration in Minnesota school

Location: White Bear Lake, Minnesota

Services: Mechanical, electrical, and plumbing

Category: Education/day-care center

Area: 10,730 sq. ft.

Software: AutoCAD, Bluebeam, COMcheck, HAP 5.11, McQuay Duct Sizer

Ceiling height restraints in a building on two levels, each designed and renovated for day-care use for a Higher Ground School, posed special challenges for 3S MEP + structural designers in White Bear Lake.

Higher Ground schools provide day care for infants and toddlers and educational services through high school. Spaces in the schools include classrooms, Nido rooms for infants from six weeks to 16 months, toddler rooms, children’s houses, kitchenettes, classrooms, restrooms and more.

Designs guaranteed the utmost functionality, safety, and comfort for the young occupants and the adults who care for and educate them. The focus was on comfort, proper ventilation, and the efficient delivery of heating, cooling, plumbing, lighting, and power.

The plumbing team designed water supply and sanitary waste disposal systems and a grease disposal system for kitchen services. Our primary emphasis revolved around guaranteeing adequate supply, effective drainage, and compliance with plumbing standards and codes. Plumbing fixtures were chosen as appropriate for the varying water and sanitation requirements for the spaces in the facility.

Electrical designs provided lighting and power layouts that considered both functionality and energy efficiency. The team conducted load calculations to determine the electrical demand and developed an SLD to illustrate the electrical connections and distribution within the facility.

The HVAC system uses furnaces, and condensing units with economizer systems for optimal heating, cooling, and ventilation. The 3S HVAC team designed a system to meet the requirements of multi-utility facilities. Wall caps were used for efficient air intake and exhaust and to maintain proper pressure in each room.

Design adhered to ICC codes to comply with industry regulations and guarantee the highest standards of safety and quality.

With all 3S MEP projects, a primary focus is integrating MEP and structural designs with the construction and architectural partners and the end-users to minimize the need for design adjustments or revisions during the construction process. Design teams from 3S MEP actively engage with all stakeholders to identify potential conflicts and optimize overall system layout. Our teams are exceptionally proficient at harmonizing essential building elements for successful outcomes.