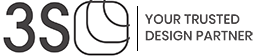

Cleanroom

Cleanrooms for biotech, pharmaceutical, semiconductor, military and aerospace industries bring special considerations for the design of HVAC systems. The requirements are much more stringent than for conventional HVAC.

First, cleanrooms require from 15 to 300 or more air changes per hour compared to two, three or four in a standard commercial or home space.

In addition to increased air supply, they also have special needs for airflow patterns, high-efficiency HEPA filters and room pressurization. Controls for temperature and humidity need a much greater degree of precision, depending on the processes that will take place inside the rooms.

And all of this is in addition to the fact that people working in the rooms need a safe, comfortable environment.

3S MEP + Structural has worked with a variety of pharmaceutical companies to provide support for renovation, expansion, and new construction.