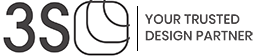

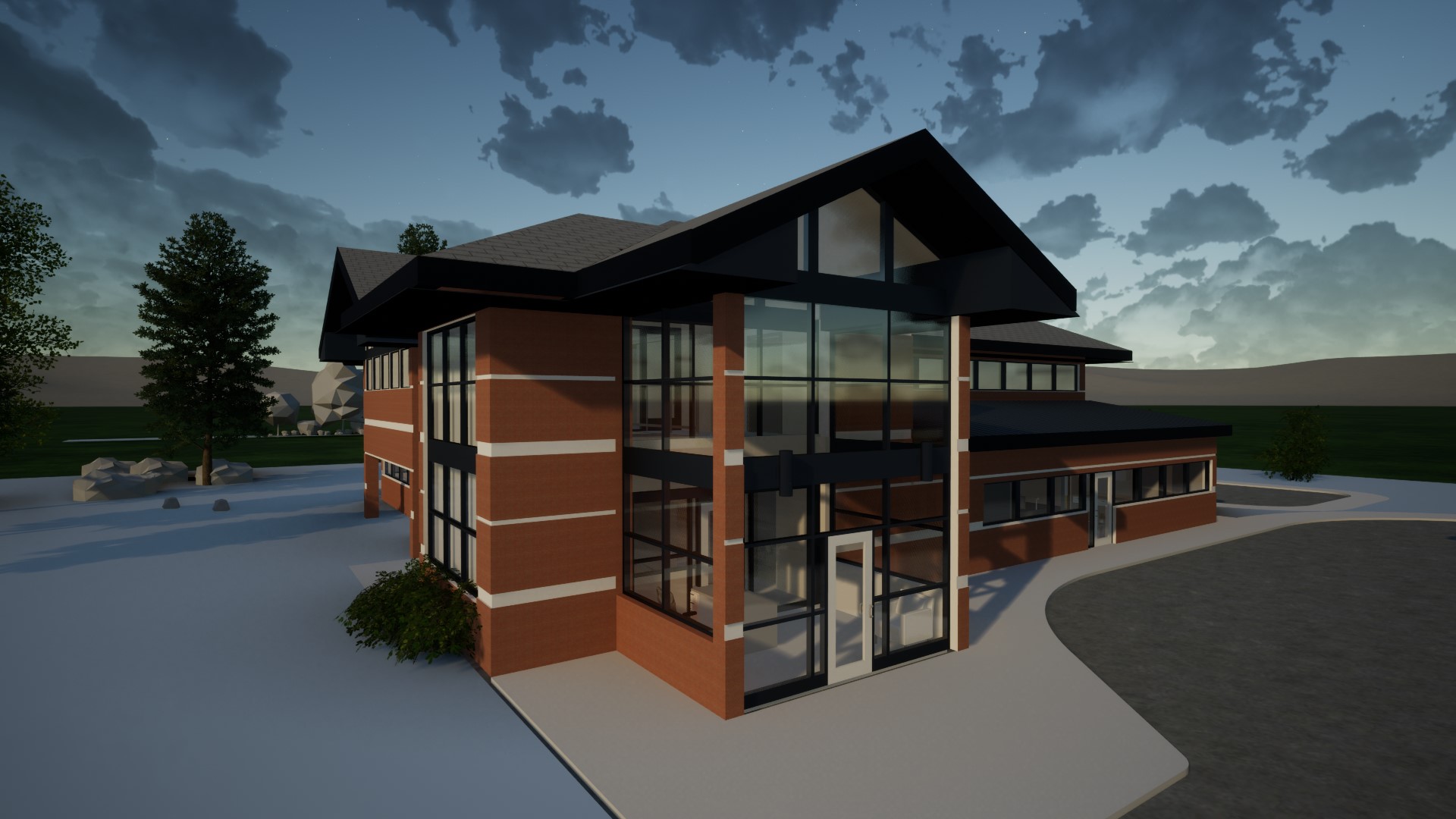

HIGHER GROUND, APPLE VALLEY, MN.

Location: Apple Valley, MN

Services: Mechanical, Electrical, and Plumbing

Category: Education- Day care center

Area: 8,740 sq. Ft

Software: AutoCAD, HAP 5.11, Bluebeam, COMCheck, McQuay Ductsizer

3S MEP provided exhaustive Mechanical, Electrical, and Plumbing (MEP) design services for the Higher Ground School endeavor situated in Apple Valley, Minnesota. Encompassing an expansive 8740 sq.ft facility, the project featured MEP intricacies within Toddler rooms, with a pivotal emphasis on assuring occupant comfort, adept ventilation, and the efficient dispensation of heating, cooling, plumbing, lighting, and power services.

The project posed a challenge to relocate and utilization of existing furnace unit in way to meet the HVAC demand.

The plumbing division designed the domestic water supply, sanitary waste disposal, and the installation of a grease system for the kitchen service. Our main focus was to ensure proper supply, efficient drainage, and adherence to plumbing codes and regulations. Careful consideration was given to the selection of plumbing equipment and fixtures to meet the specific domestic water demands of the school facility.

Electrical design services included lighting and power layout that considered both functionality and energy efficiency. The team conducted load calculations to determine the electrical demand and designed the electrical system accordingly. Developed a Single Line Diagram (SLD) to illustrate the electrical connections and distribution within the facility.

The major obstacle encountered in this project pertained to the development of the lighting system within the double-height space. The 3S electrical team effectively addressed and overcame this challenge, successfully executing the lighting design in conjunction with the completion of the necessary COMcheck assessments.

The HVAC system was designed using a existing furnaces, and condensing units with economizer systems as needed for optimal heating, cooling, and ventilation. We utilized Wall cap for efficient air intake and exhaust, maintaining proper pressure in each room for human comfort. We designed an adequate HVAC system to meet the requirements of multi-utility facilities such as toddlers, Nido, Children’s Houses, kitchenettes, restrooms, and other areas within the school.

The project encountered multiple challenges that needed to be addressed. Firstly, it was crucial to effectively coordinate the mechanical, electrical, and plumbing (MEP) systems to ensure seamless integration and functionality. Additionally, a major focus was placed on avoiding any design alterations or modifications that could potentially disrupt the overall project timeline and budget. Throughout the MEP project, strict adherence to ICC codes was paramount, ensuring compliance with industry regulations and guaranteeing the highest standards of safety and quality.